Plastic pollution has become one of the biggest challenges of the modern world. Every year, millions of tons of plastic waste end up in our oceans, harming marine life and ecosystems. To tackle this problem, researchers and scientists have been exploring various methods of plastic recycling. One such method is transforming plastic into oil.

The idea behind transforming plastic into oil is to break down the large polymer chains of plastic into smaller hydrocarbon molecules, which can then be refined into usable fuels. This process, known as thermal depolymerization, involves subjecting the plastic to high temperatures and pressure in the absence of oxygen. Through this process, plastic can be converted into various types of oil, such as diesel, gasoline, and even crude oil.

While the concept of transforming plastic into oil holds promise, there are several challenges that need to be overcome. Firstly, the process requires a significant amount of energy, which may not be cost-effective or environmentally friendly. Additionally, the quality of the oil produced may not be as high as that obtained from traditional sources. Furthermore, there is a concern that transforming plastic into oil may perpetuate our dependency on fossil fuels instead of promoting sustainable alternatives.

- Transforming Plastic into Oil: Is it Possible?

- The Concept: From Plastic Waste to Oil

- The Challenges and Limitations

- The Problem of Plastic Waste

- The Potential of Plastic-to-Oil Conversion

- The Benefits of Plastic-to-Oil Conversion

- Challenges and Considerations

- How Plastic-to-Oil Conversion Works

- Challenges and Limitations

- The Environmental Impact

- Reducing Plastic Waste

- Energy Consumption and Emissions

- The Future of Plastic-to-Oil Technology

- Q&A

- Is it possible to transform plastic into oil?

- How does pyrolysis work?

- What are the benefits of transforming plastic into oil?

- What are the challenges of transforming plastic into oil?

- Are there any companies or initiatives working on transforming plastic into oil?

Transforming Plastic into Oil: Is it Possible?

Plastic pollution is a major environmental concern that continues to worsen with each passing year. The accumulation of plastic waste in landfills and oceans has led to devastating consequences for ecosystems and wildlife. As a result, there has been increasing interest in finding innovative solutions to tackle this global issue.

The Concept: From Plastic Waste to Oil

One proposed solution that has gained attention is the transformation of plastic waste into oil. This concept involves using advanced technology to break down plastic polymers into their basic molecular components, which can then be transformed into a usable form of oil.

The process typically involves the following steps:

- Sorting and separating plastic waste based on its type and composition

- Shredding the plastic into smaller pieces

- Heating the shredded plastic in a controlled environment, such as a pyrolysis reactor, without the presence of oxygen

- Breaking down the plastic polymers into smaller hydrocarbon molecules

- Condensing and cooling the resulting vapors to obtain a liquid oil-like substance

This oil-like substance can then be further refined and processed to produce various fuels, such as gasoline, diesel, or even jet fuel.

The Challenges and Limitations

While the concept of transforming plastic into oil seems promising, there are several challenges and limitations that need to be considered:

- Availability and collection of plastic waste: Ensuring a steady and reliable supply of plastic waste for the conversion process.

- Sorting and contamination: Proper sorting and separation of different types of plastic, as well as removing any contaminants, is crucial for the success of the process.

- Energy consumption: The transformation process requires a significant amount of energy, which can impact its overall sustainability.

- Economic viability: The cost of implementing the technology and the value of the end product need to be carefully evaluated to determine the economic viability of the process.

- Emission of greenhouse gases and other pollutants: The transformation process can potentially release greenhouse gases and other pollutants, which can contribute to air pollution and climate change.

Despite these challenges, researchers and innovators are actively working on improving the efficiency and sustainability of the plastic-to-oil conversion process. Through advancements in technology and increased awareness about plastic pollution, it is possible that transforming plastic into oil could become a viable solution for addressing the global plastic waste crisis.

The Problem of Plastic Waste

Plastic waste has become a global environmental crisis. The production and consumption of plastic have increased significantly over the past few decades, leading to a massive accumulation of plastic waste in landfills, rivers, and oceans.

Plastic is a durable and versatile material, which has made it highly popular in various industries. However, its durability is also its downfall. Unlike natural materials, plastic does not decompose easily and can take hundreds of years to break down.

According to the World Economic Forum, the world produces over 380 million tons of plastic waste each year. This waste is causing severe damage to ecosystems and wildlife. Plastics are mistaken for food by marine animals, leading to their ingestion and often resulting in death. Additionally, plastic waste can release toxic chemicals into the environment, contaminating soil and water sources.

Efforts to recycle plastic have not been sufficient to address the growing problem. Only a small percentage of plastic waste is recycled globally, with the majority ending up in landfills or being incinerated. The recycling process is also energy-intensive and expensive.

To combat the problem of plastic waste, it is crucial to reduce plastic consumption and find alternative materials that are biodegradable or easier to recycle. Many countries and organizations are implementing initiatives to ban single-use plastics and promote the use of eco-friendly materials.

Technological advancements are also being made in converting plastic waste into usable products, such as fuel or other chemicals. The process of transforming plastic into oil, for example, shows promise as a potential solution to reduce plastic waste and reliance on fossil fuels.

| Key Statistics | |

|---|---|

| World plastic waste production per year | Over 380 million tons |

| Percentage of plastic waste recycled globally | Small percentage |

| Time taken for plastic to decompose | Hundreds of years |

The Potential of Plastic-to-Oil Conversion

Plastic pollution has become a global concern, with millions of tons of plastic waste ending up in our oceans and landfills each year. Finding sustainable solutions to manage this waste is crucial for our environment and future generations. One innovative approach is plastic-to-oil conversion, a process that transforms plastic waste into usable fuel.

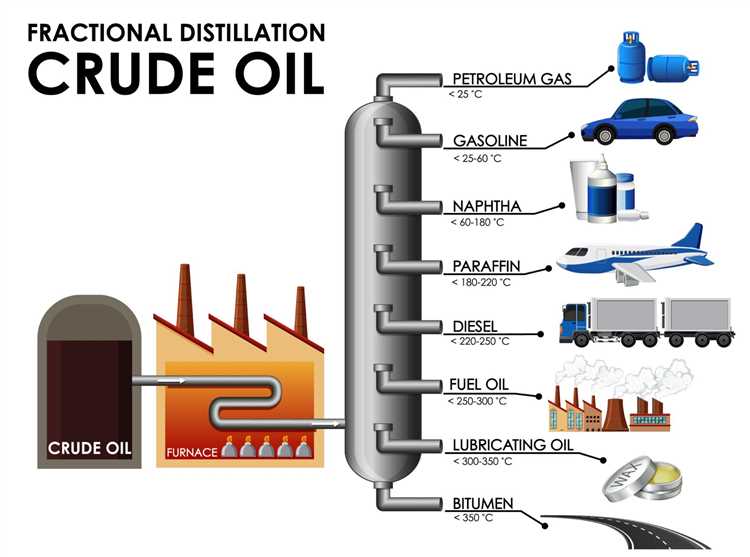

Plastic-to-oil conversion involves the pyrolysis or depolymerization of plastic waste, where heat and pressure are used to break down the long chains of polymers and transform them into oil. This oil, known as pyrolysis oil or synthetic crude oil, can be further refined into various products, including gasoline, diesel, and other petroleum-based products.

The Benefits of Plastic-to-Oil Conversion

Plastic-to-oil conversion offers several potential benefits:

- Waste Management: By converting plastic waste into oil, this process helps reduce the amount of plastic in landfills and oceans, effectively managing and diverting waste from traditional disposal methods.

- Energy Generation: Pyrolysis oil can be used as a source of energy, replacing traditional fossil fuels and reducing greenhouse gas emissions.

- Resource Recovery: Plastic waste is a valuable resource that can be converted into usable products, reducing the need for virgin materials and supporting a circular economy.

- Economic Opportunities: The plastic-to-oil conversion industry can create new job opportunities and stimulate economic growth.

Challenges and Considerations

While plastic-to-oil conversion holds promise, there are several challenges and considerations to address:

- Environmental Impacts: The process of plastic-to-oil conversion requires energy and emits greenhouse gases, raising concerns about its overall environmental impact.

- Quality and Consistency: The quality and consistency of the pyrolysis oil produced can vary depending on the type and composition of the plastic waste used, which may impact its usability and marketability.

- Economic Viability: The costs associated with plastic-to-oil conversion, including the collection, sorting, and processing of plastic waste, need to be considered for the technology to be economically viable.

- Policies and Regulations: Implementing plastic-to-oil conversion on a larger scale would require supportive policies and regulations to ensure the safety, efficiency, and sustainability of the process.

In conclusion, plastic-to-oil conversion has the potential to address the plastic waste crisis and provide a sustainable solution for managing plastic waste. However, further research, development, and investment are needed to overcome the challenges and maximize the benefits of this innovative technology.

How Plastic-to-Oil Conversion Works

Plastic-to-oil conversion is a fascinating process that has gained significant attention as a potential solution to the plastic pollution problem. This process involves the transformation of plastic waste into usable fuel, such as crude oil or diesel, through various chemical processes.

The first step in plastic-to-oil conversion is the sorting and cleaning of the plastic waste. This involves removing any non-plastic materials, such as paper or metal, from the waste stream. Once the waste is sorted, it is shredded into smaller pieces to increase the surface area for subsequent steps.

After the initial preparation, the shredded plastic waste is heated in a controlled environment, typically in a pyrolysis reactor. Pyrolysis is a thermal decomposition process that occurs in the absence of oxygen, preventing the plastic from burning. The plastic is gradually heated to a specific temperature, causing it to break down into smaller molecules.

As the plastic is heated, it undergoes a series of chemical reactions, breaking down into different hydrocarbon compounds and gases. These compounds are then condensed and cooled to collect the liquid fraction, which consists of the desired fuel product. The gases formed during the process can also be captured and used as an additional energy source.

The resulting crude oil or diesel can be further processed to remove impurities and enhance its quality. It can then be used as a fuel source for various applications, such as powering vehicles or generating electricity. Alternatively, the fuel can be further refined to produce other petroleum-based products, including plastics for manufacturing.

Plastic-to-oil conversion offers several advantages over traditional waste management methods. It provides a way to reduce plastic waste and its environmental impact, as well as address the growing demand for fuel alternatives. Additionally, this process can generate economic opportunities by creating a new industry around plastic recycling and energy production.

However, plastic-to-oil conversion is not without its challenges. The process can be energy-intensive and requires careful control of temperature and other factors to ensure efficient conversion. Moreover, the scalability and cost-effectiveness of this technology are still under scrutiny, as further research and development are needed.

Nevertheless, plastic-to-oil conversion holds promise as a potential solution to the plastic pollution problem. With ongoing advancements in technology and increased awareness of the environmental consequences of plastic waste, this innovative process may become an integral part of a sustainable future.

Challenges and Limitations

While the idea of transforming plastic into oil holds great promise for addressing the global plastic waste problem, there are several challenges and limitations that need to be considered.

Contamination: One of the major challenges in the process of converting plastic into oil is the presence of contaminants in the plastic waste. Plastics often contain impurities such as paper, labels, and other materials that can affect the quality of the final product. Efforts are being made to develop efficient methods to remove these contaminants, but it remains a significant challenge.

Economic viability: Another limitation is the economic viability of the process. While the technology to convert plastic into oil exists, the cost of setting up and operating these facilities can be high. In many cases, the cost of producing oil from plastic is higher than the price of crude oil, making it less financially attractive for investors.

Energy input: The transformation process requires a considerable amount of energy input. This energy is needed to heat the plastic to high temperatures, break it down, and convert it into oil. The energy required can be a limiting factor, especially if the source of energy is not renewable or sustainable.

Scale and infrastructure: Scaling up the process to handle large quantities of plastic waste is another challenge. Currently, most plastic-to-oil facilities operate at small scales, and there is a lack of infrastructure for large-scale implementation. Developing the necessary infrastructure and logistics to handle and process large volumes of plastic waste is a significant limitation.

Environmental impact: While converting plastic into oil can help reduce plastic waste, it is essential to consider the environmental impact of the process itself. Some methods of plastic-to-oil conversion may release greenhouse gases and create air and water pollution. Ensuring that the process is environmentally friendly and sustainable is crucial.

Regulatory hurdles: The implementation of plastic-to-oil conversion technologies may also face regulatory hurdles and challenges. Governments and regulatory bodies need to establish guidelines and regulations to ensure the safe and efficient operation of these facilities and to address any potential environmental and health concerns.

In conclusion, while transforming plastic into oil has the potential to be an effective solution for plastic waste management, there are several challenges and limitations that need to be addressed. Continued research, innovation, and collaboration are essential to overcome these obstacles and make plastic-to-oil conversion a viable and sustainable option for the future.

The Environmental Impact

Turning plastic into oil has the potential to greatly impact the environment in both positive and negative ways. Here, we will explore some of the key environmental impacts associated with this process.

Reducing Plastic Waste

One of the main benefits of transforming plastic into oil is its potential to reduce the amount of plastic waste that ends up in landfills or oceans. By converting plastic waste into a valuable resource, we can minimize the need for disposal and alleviate the burden on our ecosystems. This can help to mitigate the devastating effects of plastic pollution on wildlife and natural habitats.

Energy Consumption and Emissions

While the conversion of plastic to oil offers environmental benefits, the process itself requires energy and emits greenhouse gases. The energy requirements for heating and processing the plastic can contribute to carbon emissions and air pollution. It is important to implement energy-efficient and emissions-reducing techniques to minimize the environmental impact of this conversion process.

| Environmental Impact | Description |

|---|---|

| Reduction in landfill waste | The conversion process reduces the amount of plastic waste sent to landfills, preventing further accumulation and potential harm to the environment. |

| Decreased plastic pollution | By converting plastic into a useful resource, we can reduce the amount of plastic waste that enters our oceans and threatens marine life. |

| Energy consumption | The process of transforming plastic into oil requires energy, which can contribute to carbon emissions and air pollution. |

| Emissions | The conversion process may release greenhouse gases and other pollutants into the environment if not properly managed. |

Overall, transforming plastic into oil has the potential to address the pressing issue of plastic waste, but it is crucial to implement sustainable practices that minimize energy consumption and emissions. By doing so, we can maximize the positive environmental impact of this innovative technology.

The Future of Plastic-to-Oil Technology

Plastic pollution has become a significant issue around the world, with millions of tons of plastic waste ending up in landfills and oceans each year. However, new technological advancements are offering a glimmer of hope in tackling this problem. One such innovation is converting plastic into oil.

Plastic-to-oil technology involves breaking down plastics into their basic components, such as hydrocarbons, and then converting them into usable fuel. This process not only reduces the amount of plastic waste but also provides an alternative source of energy.

In the near future, plastic-to-oil technology holds immense potential for becoming a game-changer in waste management and energy production. Here are a few reasons why:

- Reduced environmental impact: Converting plastic waste into oil can significantly reduce the environmental impact of plastic pollution. By keeping plastics out of landfills and oceans, this technology helps to preserve natural ecosystems and protect wildlife.

- Energy independence: Plastic-to-oil technology offers a way to produce valuable fuel resources domestically, reducing dependence on foreign oil imports. This enhanced energy independence can lead to economic benefits and increased national security.

- Circular economy: The conversion of plastic waste into oil creates a closed-loop system, where plastic products can be recycled and transformed into usable fuel. This contributes to the development of a circular economy, reducing resource consumption and promoting sustainability.

- Technological improvements: As the demand for alternative energy sources continues to grow, the technology behind plastic-to-oil conversion is expected to advance rapidly. With ongoing research and development, it is likely that more efficient and environmentally friendly processes will be developed in the future.

While plastic-to-oil technology is still in its early stages, its potential benefits are undeniable. However, it is important to approach this technology with caution and ensure proper regulation and waste management practices are in place. By doing so, we can harness the power of plastic-to-oil technology and create a more sustainable and eco-friendly future.

Q&A

Is it possible to transform plastic into oil?

Yes, it is possible to transform plastic into oil through a process called pyrolysis.

How does pyrolysis work?

Pyrolysis is a process in which plastic is heated in the absence of oxygen, causing it to break down into smaller molecules, which can then be condensed and converted into oil.

What are the benefits of transforming plastic into oil?

Transforming plastic into oil has several benefits. It helps reduce the amount of plastic waste in landfills and oceans, provides an alternative source of fuel, and reduces the reliance on fossil fuels.

What are the challenges of transforming plastic into oil?

There are several challenges to transforming plastic into oil. The process can be expensive and energy-intensive, and there are concerns about the emissions and environmental impact of the process. Additionally, not all types of plastic can be easily converted into oil.

Are there any companies or initiatives working on transforming plastic into oil?

Yes, there are several companies and initiatives working on transforming plastic into oil. Some examples include Plastic Energy, Agilyx, and RES Polyflow. These companies are using pyrolysis and other technologies to convert plastic waste into oil.